We are an interconnected global economy and businesses rely heavily on complex supply chains to deliver goods and services to customers. However, these supply chains are vulnerable to disruptions that can have far-reaching impacts on businesses and their ability to meet customer demands.

Let’s take a closer look at the concept of supply chain disruptions, explore their potential consequences, and outline some strategies on how to manage supply chain disruption, mitigate risks and ensure uninterrupted business operations.

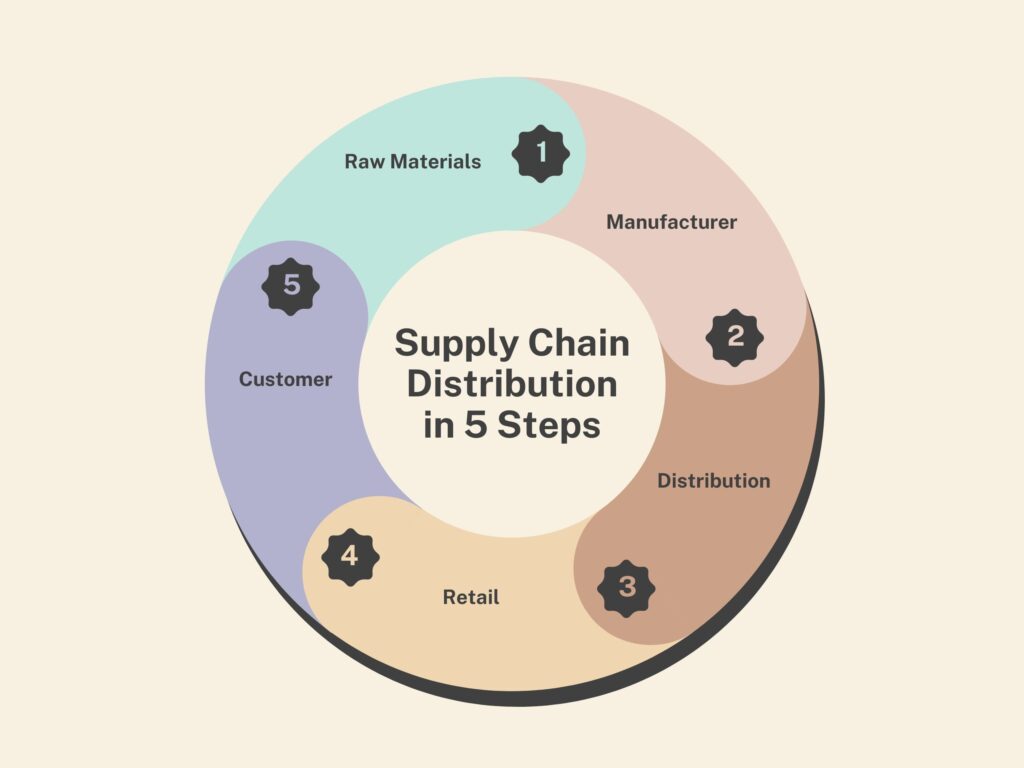

What is a supply chain?

A supply chain refers to the network of organizations, processes, activities, resources, and technologies involved in the creation, production, distribution, and delivery of goods or services from the initial raw material stage to the final customer. It encompasses the entire journey of a product, from sourcing raw materials to manufacturing, distribution, retail, and ultimately reaching the end consumer.

Why is a supply chain important?

Supply chains are important because they make sure that the things we need and want are available for us to buy and use. They help products, like the clothes we wear, the food we eat, and the gadgets we use, get to stores or our homes.

Here are a few reasons why supply chains are important:

- Availability: Supply chains make sure products are always in stock and ready for us to buy. Imagine if your favourite snacks or toys were always sold out – that’s where supply chains come in to keep things available.

- Variety: They allow us to have a wide range of choices. We can pick from different brands, styles, and options because supply chains bring all these choices to us. If you are a business owner, supply chains help with sourcing from different suppliers.

- Efficiency: Supply chains help things move smoothly and quickly. Without them, it might take much longer for products to get from where they’re made to where we want them.

- Economy: Supply chains support businesses and provide jobs. When they work well, it helps economies grow and people have work to do.

- Emergency Response: Supply chains are important during emergencies. They help deliver things like medical supplies, food, and water to places that need them urgently.

- Quality Control: Supply chains help ensure that products meet certain standards and are safe for us to use. They make sure products are made the right way.

Overall, supply chains play a big role in our daily lives by making sure the things we rely on are available, diverse, and reach us efficiently.

Understanding Supply Chain Disruptions

Supply chain disruptions refer to unexpected events or changes that disrupt the flow of goods, materials, and information within a supply chain network. These disruptions can originate from various sources.

Supply Chain Disruption Examples

Here are some of the most common supply chain disruptions:

Natural disasters (such as earthquakes, hurricanes, and floods),

Geopolitical tensions

Economic fluctuations

Labour strikes

Transportation breakdowns

Technological failures

Most recently we also felt the impact of supply disruptions due to the Covid 19 pandemic.

We should also consider the possibility of a supply disruption caused by strained relationships between a company and its supplier. Such disruptions can arise from either behavioural issues or financial challenges, such as outstanding or unpaid invoices. You should never underestimate the importance of a supplier-buyer relationship.

When a disruption occurs, it can lead to delays, shortages, increased costs, and even complete breakdowns in the supply chain.

Consequences of Supply Chain Disruptions

The consequences of supply chain disruptions can be significant and wide-ranging. Businesses may face the following:

Production Delays:

When key suppliers are unable to deliver materials on time, it can halt production lines and lead to product shortages.

Increased Costs:

Sourcing alternative suppliers or transportation methods often comes at a higher cost, impacting a company’s profitability.

Customer Dissatisfaction:

Inconsistent product availability or delayed deliveries can result in unhappy customers and damage a company’s reputation.

Inventory Issues:

Disruptions can lead to excess inventory if production stops abruptly or inadequate inventory if demand surges unexpectedly.

Financial Losses:

Businesses may experience revenue losses due to halted operations or increased expenses to manage the disruption.

How to prevent supply chain disruptions

While it’s impossible to eliminate all supply chain risks, businesses can take the following proactive steps to mitigate and prevent potential disruptions and ensure business continuity:

1. Diversify Suppliers:

Relying on a single supplier increases vulnerability. Diversifying suppliers across different regions reduces the impact of disruptions in one area.

2. Supply Chain Mapping: Create a clear map of your supply chain, identifying critical components and dependencies. This helps anticipate risks and devise backup plans.

3. Risk Assessment: Regularly assess potential risks and their potential impact on your supply chain. This should be part of your risk management. Develop contingency plans for high-priority risks. Build flexibility into your supply chain to quickly adapt to changing circumstances.

4. Communication: Maintain open lines of communication with suppliers, partners, and customers. Swift communication during disruptions allows for coordinated responses.

5. Safety Stock: Maintain safety stock of essential materials to cushion against sudden demand spikes or supply shortages.

6. Collaboration: Collaborate with industry peers and organizations to share best practices and insights for managing disruptions.

7. Supplier Relationships: Build strong relationships with suppliers based on trust and collaboration. This can lead to better support during times of disruption.

8. Insurance and Contracts: Consider insurance policies that cover supply chain disruptions. Additionally, establish clear contracts with suppliers outlining responsibilities during disruptions.

9. Scenario Planning: Develop scenarios for various disruption scenarios and simulate responses. This enhances preparedness and quick decision-making. Incorporate supply chain resilience into your long-term business strategy.

10. Employee Training: Equip employees with the skills to handle disruptions efficiently. Cross-train staff to manage multiple roles if needed. Upskilling staff is an extremely valuable task that all businesses should consider.

Conclusion

In conclusion, supply chain disruptions are a persistent threat that businesses must address to ensure seamless operations and customer satisfaction. By understanding potential risks, implementing proactive measures, and fostering a culture of adaptability, businesses can mitigate the impact of disruptions and maintain business continuity even in challenging times.